Results 14,311 to 14,320 of 20502

Thread: What are you working on?

-

10-13-2018, 01:38 AM #14311

Man! You are hard-core, Steve! I use some bog-dust and Harbor Freight CA!

Stuff like that goes bad before I can use it, sadly.

Regards,

Short Term Tom

-

10-13-2018, 01:53 AM #14312

Yeah, been there done that. Tired of CA drying up on me. This stuff is worth it. Been wanting to try the white on ivory but haven't yet.The skinny end of the whip tips fit in the red tube on the canned air & I am able to blow the excess out from both ends. I then used a twisted piece of tissue w/un-cure & a piece of copper wire I have & I get it clean every time.

-

The Following User Says Thank You to engine46 For This Useful Post:

sharptonn (10-13-2018)

-

10-13-2018, 02:27 AM #14313

Thanks Steve! I'm always adding to and editing my tools and supply list.

I haven't bought new CA yet, planning on getting thin and thick, now ill need to add black CA!

Probably have a little different look than Bog CA..?

Maybe for different scale finishes or materials?“You must unlearn what you have learned.”

– Yoda

-

10-13-2018, 02:33 AM #14314

See, that's what I'm talking about.

There is so much knowledge in this thread alone. I'd be lost in this hobby without it!

-

10-13-2018, 02:36 AM #14315

I suppose getting lots of projects lined-up for it (and actually doing them) are paramount to getting the money's worth within a year or so?

Stuff looks 'spensive.

-

10-13-2018, 02:57 AM #14316

Yep. I have one bottle of the Bob Smith Industries that dried up but not before I used it a lot. I have medium & thick but I hardly ever use those. That un-cure is some good stuff. It dissolves the CA enough to get it off my fingers. I used to sand it off my fingers! It worked. I got that off the bay a couple years ago.

I recently pinned a razor together but need to finish honing it. It's a Crandall Cutlery for my Case family collection. I had the blade only & I used some rope scales like they originally used back then. it was perfect but someone must have come around one time when I wasn't home & I had everything in my master br when my dog must have been going crazy because I got home & it was a mess. Lucky it wasn't worse. A tiny nick under the 'T" in Kut.

I had my Top Flight out not long ago & now I can't find it but I will.

-

10-13-2018, 03:11 AM #14317

-

10-13-2018, 04:02 AM #14318

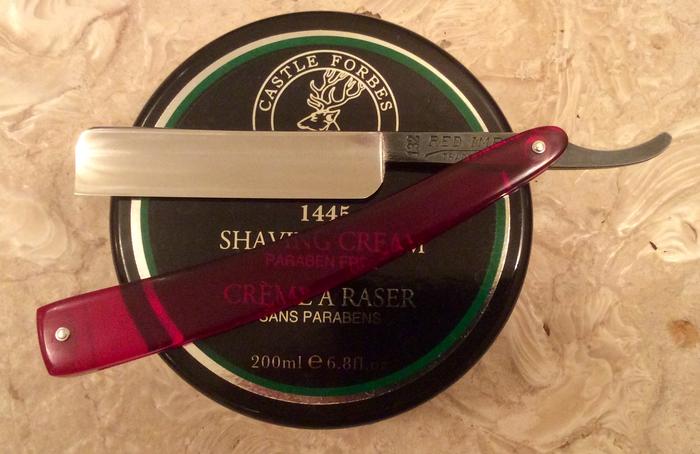

Case Red Imp Wedge

Case Red Imp Wedge

I’ve been looking for a chance to buy a Case Red Imp 132 at a reasonable price, and just got one. Blade was in good shape, but old rubbery scales.

Polished, re-blued, new scales, and honed up for tomorrow:

-

10-15-2018, 05:35 AM #14319

Got my Crandall honed, just needs stopping. i started with the green brick followed by 2k, 3k, 5k Chosera's then to my Snow White, 10k Chosera & 20k Suehiro. this time I made a slurry with each gradually ending up with just water.

-

10-15-2018, 11:16 AM #14320

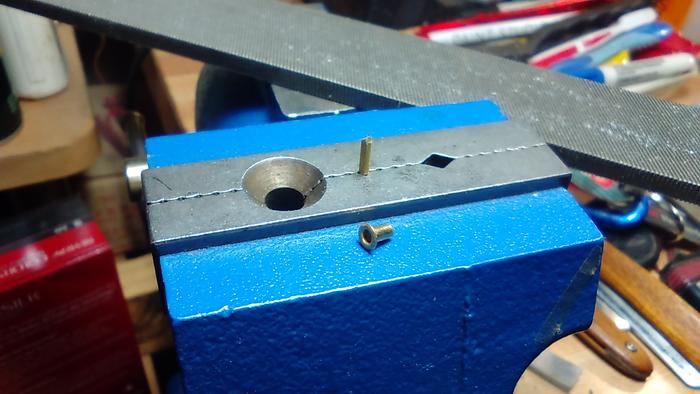

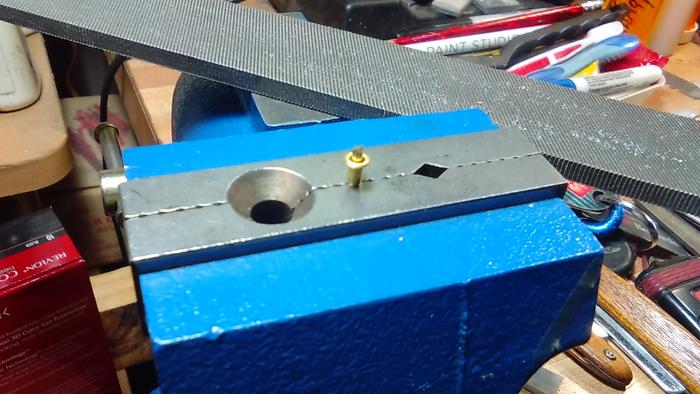

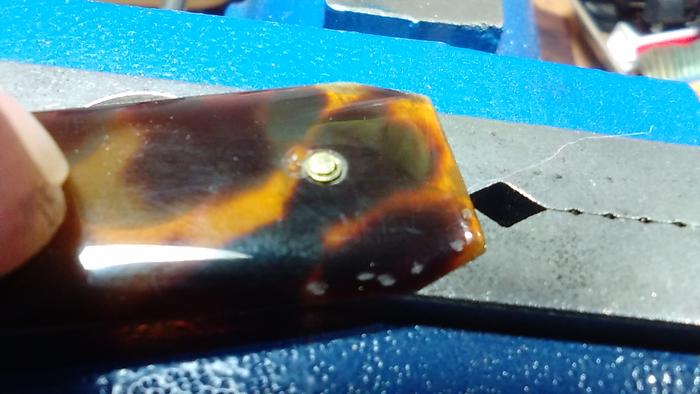

Started work on a Bencini, for MikeT. Its in pretty good condition, but I still separated it to clean up the tang, and straightend out the sanding marks on the blade.

After unpinning, I realized that the pins were larger than the norm, making 1/16 rod impossible to pin with.

So....I used some rivets that Tom had sent me, to take up the slack.

To get the right thickness, I place an old piece of pinning rod in the vice, placed the rivet on the rod, filed it down till they sat just below the surface of the scales, then a drop of CA on a toothpick rubbed inside the pin holes of the scales. Lay the scales over the rivet...presto, perfectly set, and ready for pinning.

Mike

Mike

-

91280Likes

91280Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote