Results 71 to 80 of 101

Thread: Working With The Zulu Grey.

-

03-24-2018, 12:28 AM #71

A simple suggestion for reducing/ preventing rust while and immediately after honing: add some baking soda to your water. It removes any acidity of the water and hone. I had a finisher that would rust just about any carbon steel blade. I add about a tablespoonful to a liter/quart of water. (Learned from Japanese knife video)

JME

~GeezerBe yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

Raol (03-24-2018)

-

03-24-2018, 03:19 AM #72

-

03-24-2018, 07:26 AM #73Senior Member

- Join Date

- Nov 2016

- Location

- Germany

- Posts

- 111

Thanked: 30

Thank you

In a meanwhile I ve learned that high polishing the blade reduces the rusting to a certain extent. But this razor is something special, it rusts like magic

Will give a try applying soda to my honing water as you suggested.

Can I add soda also to my shave lather? Cause Caschmiso also produce some rust during shaving!

P.S. I‘ve tried to create a patina on it as its often done to carbon knifes (applying lemon juice to the blade). Not good idea, that treatment has exponentially increased the rusting. My guess is the lemon juice has increased the effective surface of the steel by etching new „holes“ in it. Had lots of fun polishing the surface „back to the old status“.

Regards

Philipp

-

03-24-2018, 01:09 PM #74

Wow. That long huh? I got plenty so i guess i could give it a try.

I did touch-up my Kama on the Zulu last night before my shave. Guessing 150 laps with very little water on the stone. Basicly just damp.

Comfy shave.

Problem with the comfy shave is, it feels as if i could do 10 full passes and not have problems.

Could have been a little keener in my opinion. Maybe the dry honing will make it more to my liking.Last edited by Gasman; 03-24-2018 at 01:35 PM.

It's just Sharpening, right?

Jerry...

-

12-28-2018, 12:14 PM #75Senior Member

- Join Date

- Nov 2016

- Location

- Germany

- Posts

- 111

Thanked: 30

Hi all,

since I've came accross some shallow finishing stones i am also more and more getting into the use of my shallow Zulu Grey stone, it measures approx. 1x7 inches.

What i've done is i've re-lapped it to have a convexity from side to side. by this I am not running into a risk to ruine the edge of the razor by running it over the edge of the stone.

Hope it is visible here in this picture:

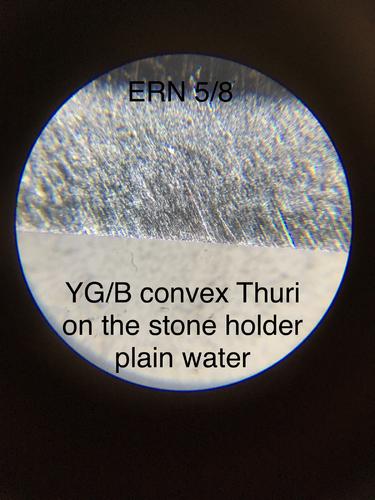

btw. the same convexity is also applied to my shallow YG/B-Thuringian.

Today have put a Zulu-finish on the ERN 5/8 razor which has been finished by the Thuringian before.

Tt has given a very comfortable shave but i had a feeling of little bit lacking keeness, it was like 4.9 points on a scale of 0 to 5.

Here is the setup:

My slurry stone does have also a convexity but it's running lengthwise, this has significantly improved the slurry-ability

Here is the picture of the edge before, having the thuri-finish to it (160x).

Please don't pay much attention to the corners of the picture, my optical system is not the best...

The center should be fine.

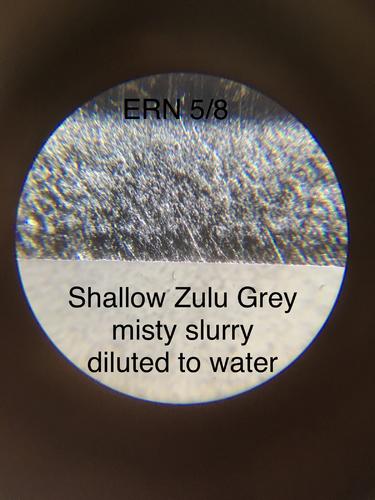

So I've created a misty/cloudy slurry on the ZG and worked the edge for a while.

Btw when I run the razor over a shallow stone I don't try to run the whole razor-edge from tip to hill during one stroke.

I rather only try to cover about 1/3 to 1/4 of the razors edge. Next stroke i move the razor a little bit to cover another section, partialy overlapping the previous one.

After a while I've started to dilute the slurry by dipping the razor into a cap with water every 20 strokes or so.

Finaly i've washed the stone and the razor and worked a little bit more on the plane water.

Here is the pic of the edge with Zulu-finish.

Edge has passed the HHT4 to HHT5 on the thinnes hairs i have, meaning i can got for a test shave.

Sadly need to wait for 2 days as my last shave is just hours ago.

Regards

Philipp

-

12-28-2018, 02:34 PM #76Senior Member

- Join Date

- Nov 2016

- Location

- Chicago Suburbs

- Posts

- 1,091

Thanked: 292

In various parts of the world, water quality varies significantly. If your water is sightly salty or slightly acidic, it will seriously contribute to corrosion of a carbon steel blade. Although it might not seem plausible, distilled or deionized water is also highly corrosive.

If your water is acidic, Richard's (geezer) suggestion of adding baking soda to your honing water will neutralize acids. The amount required depends on how acidic your water is in the first place. In some localities, the water is slightly alkaline and the soda is not needed. You can determine the acidity/alkalinity of your water by contacting your water supplier or purchasing a pH test kit such as are used by those who keep tropical fish.

-

-

12-28-2018, 04:46 PM #77

I had mixed opinions on my Zulu stone. In the end i never found it is keen as I like an edge. Thanks for bringing this back up. Maybe this weekend i will give it another try.

As far as a curved stone, ive always thought it might be a good idea, but you are concentrating all the weight/preasure onto one spot on the edge. This is why i wonder about it. It would be even more important to keep a light stroke. Doing different honing methods is part of the fun!It's just Sharpening, right?

Jerry...

-

12-28-2018, 04:55 PM #78Senior Member

- Join Date

- Nov 2016

- Location

- Germany

- Posts

- 111

Thanked: 30

One thing I am trying from time to time in order to further reduce the pressure:

I do hold the hone in my hand and tilt it by bringing one end of the stone down. The more your tilt the more the more vertical becomes your stroke. By this the razor don’t press to the stone with all irs waight, cause its tilted.

You can even hold the hone nearly vertical ant let the blade nearly glide along its surface.

Philipp

-

12-28-2018, 05:06 PM #79Senior Member

- Join Date

- Dec 2016

- Posts

- 283

Thanked: 61

A few years back, when I first decided I wanted to try naturals, I was extremely interested in the Zulu Grey and thought for sure it would be my first natural finisher. For a variety of reasons that never happened and my interest in the stone gave way to others. What still strikes me about this stone, though, is that despite how varied people's experience with them is, with some people really not particularly enjoying it, they very rarely come up for sale anywhere. In fact, I can't recall the last time I saw one pop up!

-

12-28-2018, 06:45 PM #80Senior Member

- Join Date

- Nov 2016

- Location

- Germany

- Posts

- 111

Thanked: 30

Maybe they all wait until Zulu Grey‘s quarry is closed...

;-)

130Likes

130Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote