Results 1 to 10 of 10

16Likes

16Likes

Thread: Honing bellied hollow / double grind after restore

-

06-10-2018, 02:54 PM #1Member

- Join Date

- Jan 2018

- Location

- CA

- Posts

- 70

Thanked: 23 Honing bellied hollow / double grind after restore

Honing bellied hollow / double grind after restore

Good Morning Gents,

I thought I might be posting this in the restoration section today, but instead I'm here trying to verify what I *think* is happening. This is a Friedr Herder Abr Sohn 172 that has had a rough life. I removed quite a bit of metal hand sanding over the last few weeks as time allowed, made up scales yesterday and then went to work on the edge.

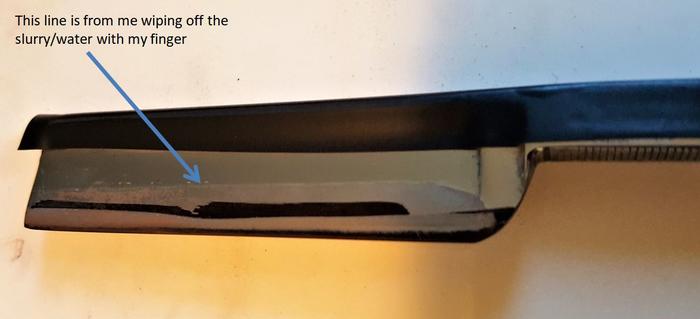

Using 1 layer of tape and working on a King 1k, I can see that I am only removing metal from the bellied part of the blade just above the edge. I put in about 30-40 minutes trying to get to the edge and then stopped for the day and took this pic.

Before taking this picture I made a large line along the edge with a sharpie, then I made about 5 x strokes on each side. The line now looks like two black lines - the area in the middle is the only part that is making contact with the hone. The opposite side is nearly the same, but getting very close to the edge after the work I put in. (There was still water and slurry on the blade so I wiped it off between the spine and the belly, but I didn't wipe where the marker was because I didn't want to wipe the marker off..I should have left it alone because now here I am over-explaining the weird line on the blade)

I just want to make sure I'm not missing something here. I guess I removed more metal from the edge of the spine than from the belly area while doing the hand sanding work, which has led to the situation I find myself in now.

I just need to continue with moderate pressure on low grit stone until I get to the edge right? I could use more than 1 layer of tape so I don't have to replace it as often, but then I'd just have to work through that eventually also if I plan to finish with 1 layer...

Here is a pic showing the grind. This was around the mid-point of hand sanding

Here are a couple of as received images

-MickeyThey even have a name for it dear, it's called Razor Acquisition Disorder...

-

The Following User Says Thank You to cwomg For This Useful Post:

Toroblanco (06-10-2018)

-

06-10-2018, 03:06 PM #2At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,957

- Blog Entries

- 1

Thanked: 13223

let me give you a restore hint

When dealing with an unknown after a restore and getting it on the hones, start with 3 layers of tape and see "Where you are at "

Also, you broke rule #1 of an unknown restore, "Set a bevel BEFORE restoring the razor" This assures you of two facts.

#1 You have clean solid steel to work with

#2 You know the starting geometry of the razor

Hope that helps

Edit:

I just came back to this when I remembered the make of the razor, Several years back I want to say 09 there was a glut of Herder blanks that hit eBAY they were not finished razors they needed the final grind and Temper

I remember they had overly thick blades and exhibited the same issues

May or may not apply hereLast edited by gssixgun; 06-10-2018 at 03:11 PM.

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

The Following 3 Users Say Thank You to gssixgun For This Useful Post:

cwomg (06-10-2018), Lazarus (06-10-2018), Toroblanco (06-10-2018)

-

06-10-2018, 03:10 PM #3

I have never seen a straight razor with a profile like that. That is one thick blade. It almost looks like the grinding process was not finished.

Did you think the spine a lot?

You may have to remove steel from the belly to get a normal bevel angle on the edge. Otherwise you may have to build up the spine and live with a larger than normal bevel angle.

-

06-10-2018, 03:54 PM #4

Agree with the previous comments. Your second picture does not look like the any finished razor I have ever seen and not like the F Herders I have owned and seen which are full hollow. It looks like a blank that had not been finished.

Last edited by Lazarus; 06-10-2018 at 03:58 PM.

-

06-10-2018, 04:26 PM #5

-

06-10-2018, 04:36 PM #6Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,250

Thanked: 3221

From the photo of the toe end on it looks like no bellied hollow I have used. It looks far too thick in the web between the belly and spine and also between the belly and edge. The only thing I can think of is to do like Glen suggested and use 3 layers of tape so you are not touching the belly and go with whatever bevel angle you finally get. I'd also use light strokes not to flex the blade moving the belly toward the hone to make contact with it. The only other alternative looks to be a regrind and temper.

BobLife is a terminal illness in the end

-

06-10-2018, 05:35 PM #7Member

- Join Date

- Jan 2018

- Location

- CA

- Posts

- 70

Thanked: 23

Thanks for the solid replies, they are greatly appreciated.

Well that could certainly explain the grind issue. I thought it was odd, but I didn't' realize it was *that* odd. The metal seems plenty hard, so I'm hoping the temper was completed at least. I'll keep at it and see what I can make happen.I just came back to this when I remembered the make of the razor, Several years back I want to say 09 there was a glut of Herder blanks that hit eBAY they were not finished razors they needed the final grind and Temper

I remember they had overly thick blades and exhibited the same issues

Of course I had read that here...but I don't always learn my lessons without a good real life example or reason... at least this lesson didn't require any bleedingAlso, you broke rule #1 of an unknown restore, "Set a bevel BEFORE restoring the razor" This assures you of two facts. I guess I'll take the next one off of my magnetic sanding block and see if I can get a bevel worked out.

I guess I'll take the next one off of my magnetic sanding block and see if I can get a bevel worked out.

Thanks again; I'll follow up after I put some more work in.They even have a name for it dear, it's called Razor Acquisition Disorder...

-

06-10-2018, 06:04 PM #8

I have a few of the Herder stamped blanks.

Yes, as Glen says, they can be a beast to hone. It was my first experience with a blank and I used a cheap Dremel wet grinder to even things out.

Since then I tool the rest of the blanks, unground, and put them into a 420 F oven. ( Carefully watched with a thermocouple on the screen they were on) and they got a nice gold color and we have gotten 3 of them to contour and shaving and the original has its edge after all this time.

YMMV as they were really gnarly when received.

Worth the effort!!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

06-10-2018, 08:05 PM #9

Look's like a prime candidate for a regrind! Send some pix to Max and he can have it looking like new! Herders are really good straits!

-

06-10-2018, 11:32 PM #10Member

- Join Date

- Jan 2018

- Location

- CA

- Posts

- 70

Thanked: 23

I went with 3 layers and went to town on a 600 grit stone. Can't say it was fast work, but I am working through all that belly and getting closer to the edge.

**Also** I really didn't mean to post this in the "hones" sections...should a mod want to move this to the "Honing" section, I would understand.

lol, I logged on and couldn't find my own post They even have a name for it dear, it's called Razor Acquisition Disorder...

They even have a name for it dear, it's called Razor Acquisition Disorder...

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote