Results 11 to 19 of 19

Thread: Tools of honing

-

05-08-2014, 02:29 AM #11Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Hotfuzz, do you have magnification?

How do you know that the bevel was set? The bevel looks uneven.

When a bevel breaks down it is usually because it was not fully set.

The paste you are using may be too aggressive or inconsistent in grit size and may have left deep stria on the bevel and edge causing it to chip and fail.

You must find out what is in the paste you are using and make sure that it is fine and consistent enough to polish the bevel finer than the previous stone. Just one large grit, can defeat the polishing process and cause a chip or chips.

When we speak of “Polishing” the bevel, we do not mean make it shinny, with metal polish. We mean reduce the land height of the bevel progressively making shallower and finer stria (scratch marks). This makes this the edge straighter and more comfortable on the skin.

You need magnification to first ensure the bevel is set, the bevels meet in a straight edge, it is sharp.

A razor edge is a very fragile thing and can easily be ruined.

-

05-08-2014, 08:11 PM #12Junior Member

- Join Date

- May 2014

- Location

- Riga, Latvia

- Posts

- 17

Thanked: 1

I think I can eliminate the shaving aspect as I have been shaving for almost a year with Straight razor with exchangeable blades. Beginning was harder but after practice and videos from other users and the famous Lynn I consider my self handy with the tool. I stretch my skin and use angles that are close to skin. With changable blades I get really good shave.

I have also watched videos on honing by different users. I use about 40 circles both sides and then changing X strokes with light pressure and in the end with mostly just the weight of the blade. I have my pastes on cardboard with full length of the blade and I do very light stroping like motions.

As for the paste grits - yes im not sure about the exact grit level on those. When I bought the blue one the salesman said its the finest they got but the vendor didnt supply the grit size information. And for the green one i know it has chromium oxide in it.

Also I have tested them by sharpening about 100+- (I know it ist much but still) knives and was testing the sharpness progression of blade. after 3k stone the pastes did great improvement. Then to see what paste has more grit I changed variations and form feel I can say that they are in right order.

About the bavel- well im not purely sure about it. From videos I assumed that when the blade seems sharp and kind of grips into fingers skin its ready to move away from 1k, later on similar inspection to see if the sharpness improves along all the blade. The uneven part probably is caused by the spine. But as I watched Lynn sharpen one of his knives he mentioned that the level isnt as important if your doing X swipes. He said that if he would have to correct the spine each time he restored old knives it would be pain.. or something like that.

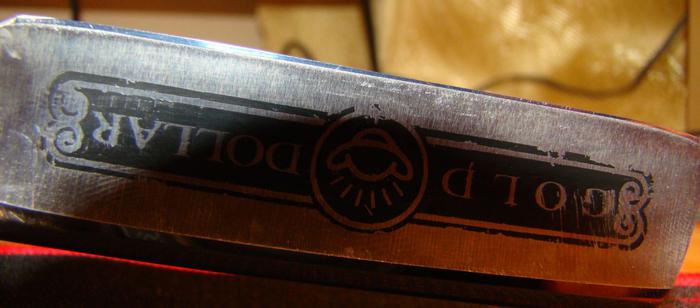

Here are some photos I tried to get the edge as big as possible..

I do realize that the progrssion and the pastes is not for the shininess but to reduce the scratch deepness into blade. The microscopic teeth becomes tinyer to easyer cut the beard. The shininess is a sub product of the goal. Scratches get smaller and light beams dont get bent so much but rather reflected back. Still metal polish does got grit and it does help to reduce the scratch thickness.

After the shave i stropped my GD again and it pops hairs from 3-4 cm distance from fingers.

-

05-10-2014, 02:09 PM #13

Im not an expert but from what I can see there still seem to be a lot of easily visible scratch marks. I would suggest that your stropping on the pastes is having an effect on the very edge of the bevel but is not enough to compensate for the lack of higher grit hones. Some of the pastes like you have also have a lot higher grits than you would think. There is a thread on here about it and in 1 case the bloke saw actually going backwards using the GREEN CHROMIUM OXIDE PASTE from a woodworking site.

My wife calls me......... Can you just use Ed

Can you just use Ed

-

05-12-2014, 05:57 AM #14Junior Member

- Join Date

- May 2014

- Location

- Riga, Latvia

- Posts

- 17

Thanked: 1

-

05-12-2014, 06:38 AM #15Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

3 to 12 is a long distance but you have more time than money so you use what you got. The 12k may get you a polished look on your bevel quicker than it gets you to sharp. So even if it looks good you may want to keep going until it is good. It's what you can't see that your trying to fix. Your lower grit stones are leaving microscopic cracks and chips that mid grit stones usually take out. By jumping to a 12k this process will take much longer. If there are no issues with the razor you should be near success.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

05-12-2014, 09:07 AM #16

It seems your tools are not quite adequate at this point. And you don't have the experience to compensate for a bit of that inadequacy, so it may take you a while to get satisfactory results.

I suppose expense is your main concern, so if you can't afford to spend the money for a good quality hone on the 6k-8k level to try and see if you'll get an improvement, then you may want to consider coarser stropping compounds, or may be lapping film (you could hone with edge leading strokes on it).

Look into the dovo line of abrasive compounds - they may be relatively easy to source in europe and the library here probably has the information on their particle sizes/grit level.

Progression of stropping on abrasive media works quite well, even though on this forum almost all discussions are about hones, and stropping on abrasives is usually done on the final stages only.

You just have to get more creative with the more limited options you have.

-

05-12-2014, 09:43 AM #17Junior Member

- Join Date

- May 2014

- Location

- Riga, Latvia

- Posts

- 17

Thanked: 1

This actually sounds realistic. Thank for advice ill try to hone it longer than usual. I have a cheap version of TAIDEA 8k stone ordered, the seller is taking forever to ship it out thought, it could take a time.. I know TAIDEA isnt probably approved by most of you guys but I read that some guys are using it for razor honing and they`re doing fine. Plus I found it really cheap. If this wont work then Ill probably gather some money and order a quality one instead.

I can now also check out the difference when honing on 12k stone and going on my ch/ox paste after to see if it improves or makes it worse.

-

05-16-2014, 02:27 PM #18

I used a taidea 3/8 to start with and finished on a barbers hone. May take a bit more lapping to keep it flat though. Good luck

My wife calls me......... Can you just use Ed

Can you just use Ed

-

05-17-2014, 12:59 PM #19Junior Member

- Join Date

- May 2014

- Location

- Riga, Latvia

- Posts

- 17

Thanked: 1

Oh good, then I'm glad it wasn't a bad purchase.

But while im waiting I had good progress. Fallowed very closely on Lynns instrucions on honing and had pretty nice results. Dont know exactly how a professionally honed razor feels like but my GD now shaves almost as good as with shavette. No cuts and burns on my last shave.

My progression was

(40circles+15 stokes)x2 on 1k,

40circles+15 stokes one time with pressure and on time without pressure on 3k

then about 15 laps on light blue compound

about 20 strokes on 12k welsh stone with slurry,

20 strokes on same 12k with just the water,

30 laps on chromium oxide pasted cardboard,

20 laps on newspaper

50 laps on leather

well with my cheap ass setup I finally did accomplish something. Im guessing with the 8k stone I would get even better results.

The main mistakes I think I made was : To much honing on stones, I spent about 20+ minutes on each stone which seems to be too much.

And also I did super light pressure after the 3k stone.

Well I think that summed up and finally lead me to some-what success. Now Ill just find someone with professionally honed strait and compare. But comparing to shavette it was quite nice.

-

The Following User Says Thank You to hotfuzz For This Useful Post:

Blistersteel (11-12-2014)

9Likes

9Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote