Results 1 to 8 of 8

Thread: How to: Washerless Pins

-

07-27-2008, 12:01 AM #1Senior Member

- Join Date

- May 2008

- Location

- Fort Wayne, IN

- Posts

- 141

Thanked: 56 How to: Washerless Pins

How to: Washerless Pins

I wanted to get a different look from my pins so I've been experimenting with using no washers and simply pinning the rod into the scales. This is actually how many peens on knife handles are done and I'm happy to report I've manipulated it for razors.

Tools:

Drill

1/16th drill bit

#6/0 Tapered Reamer

1/16th in rod stock

Sandpaper

1) Drill the 1/16th in hole in the scales just like you normally would.

2) Use the tapered reamer to expand the diameter of the hole on the outside of the scale.

3) Cut rod to length. You'll want about 1/16th extra length than what the length of the final pin will be. File flat after cutting so you get a good work surface.

4) Peen just like a normal pin but be careful to not hit the pin too hard or miss or you can risk cracking the scales.

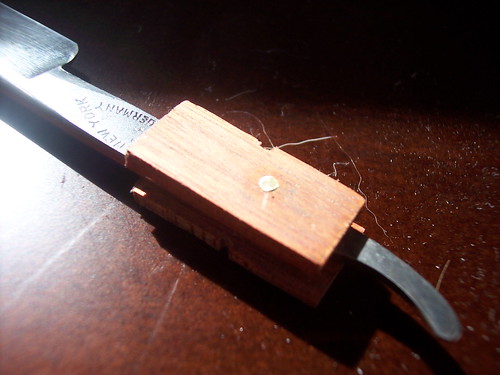

5) Sand or file the pin down flush and it should look something like this.

-

The Following User Says Thank You to AaronX For This Useful Post:

moviemaniac (07-27-2008)

-

07-27-2008, 12:08 AM #2

Nice scales!?!

I do like the flat peen on the pins though!

I do like the flat peen on the pins though! It is easier to fool people than to convince them they have been fooled. Twain

It is easier to fool people than to convince them they have been fooled. Twain

-

07-27-2008, 12:17 AM #3Senior Member

- Join Date

- May 2008

- Location

- Fort Wayne, IN

- Posts

- 141

Thanked: 56

-

07-27-2008, 02:08 AM #4

Cool! I often wondered about how they did pins like that. I thought people just epoxied them. Only thing is if you ever need to take the razor out of the scales or do something like that, the pin won't be so easy to remove huh? Might have to just snap the scales off? Either way, it's a small price to pay especially when you won't need to do it anytime soon after rescaling I'm sure.

-

07-27-2008, 02:26 AM #5Senior Member

- Join Date

- May 2008

- Location

- Fort Wayne, IN

- Posts

- 141

Thanked: 56

to remove them you can simply drill them out with the 1/16th drill bit you used for the pilot hole. This will weaken it enough to pop the pin out. But you are right they aren't as easy to remove as the washer ones where you can just dremel off the washer end.

-

07-27-2008, 02:38 AM #6Mint loving graphical comedian

- Join Date

- Oct 2007

- Location

- Bute, Scotland, UK

- Posts

- 1,526

Thanked: 131

Is that microscales I see before me, or is it a 20/8 blade?

Seriously though... super job.

-

07-27-2008, 05:05 AM #7Senior Member

- Join Date

- May 2008

- Location

- Travelling the world!

- Posts

- 223

Thanked: 36

Well done well done!

Good lateral thinkin.

+Buckler

-

07-27-2008, 07:43 AM #8

Very interesting, I might have to try this sometime

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote