Results 1 to 10 of 14

-

01-18-2013, 06:37 PM #1

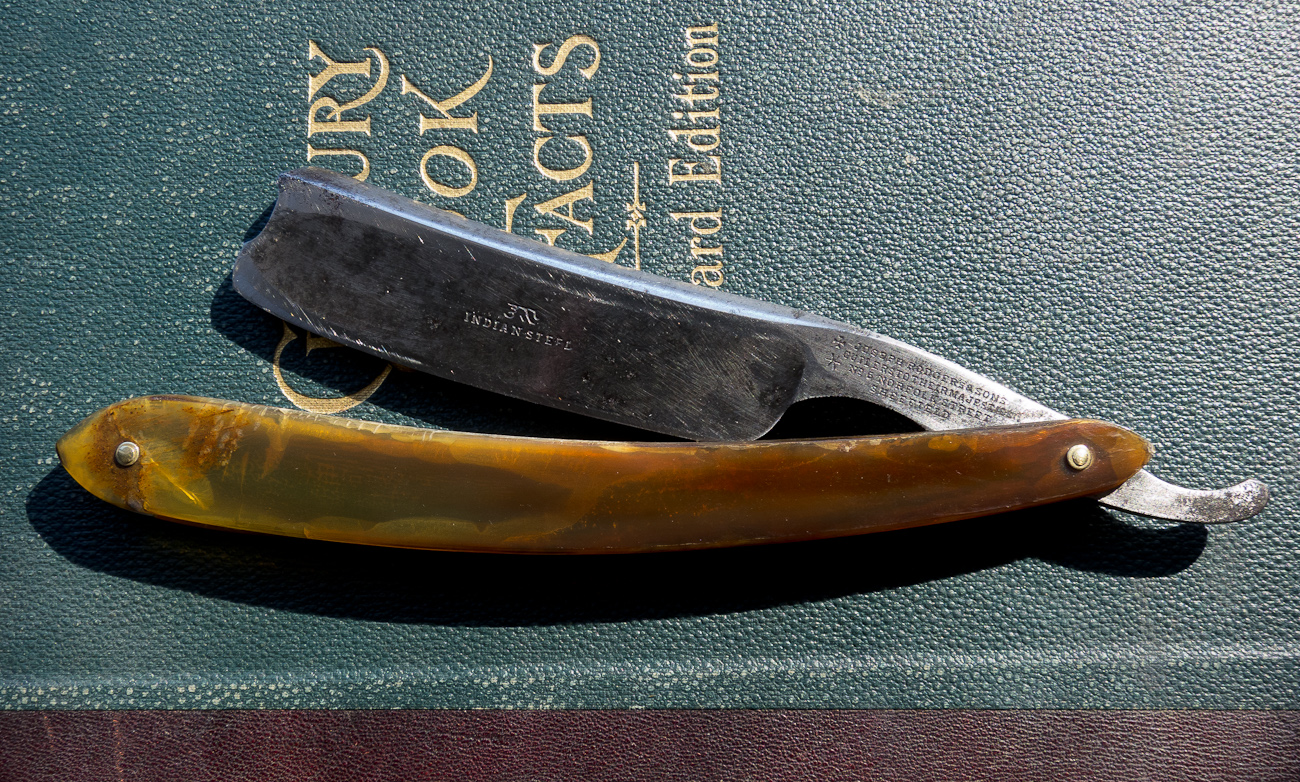

Beautiful Flaws: Joseph Rodgers 'Indian Steel' restoration.

Beautiful Flaws: Joseph Rodgers 'Indian Steel' restoration.

This is gonna be another one of those two part messages from me.

Because pictures. Lots of pictures.

I posted about this razor earlier. The symbol on the blade is the Sanskrit 'wootz'. In this case, I think it probably does mean the steel was imported, but it certainly isn't what we think of when we currently use the term (interchangeably with Damascus). My guess is that the razor is early Victorian, unless Rodgers was using the 'their Majesties' stamp during William's business.

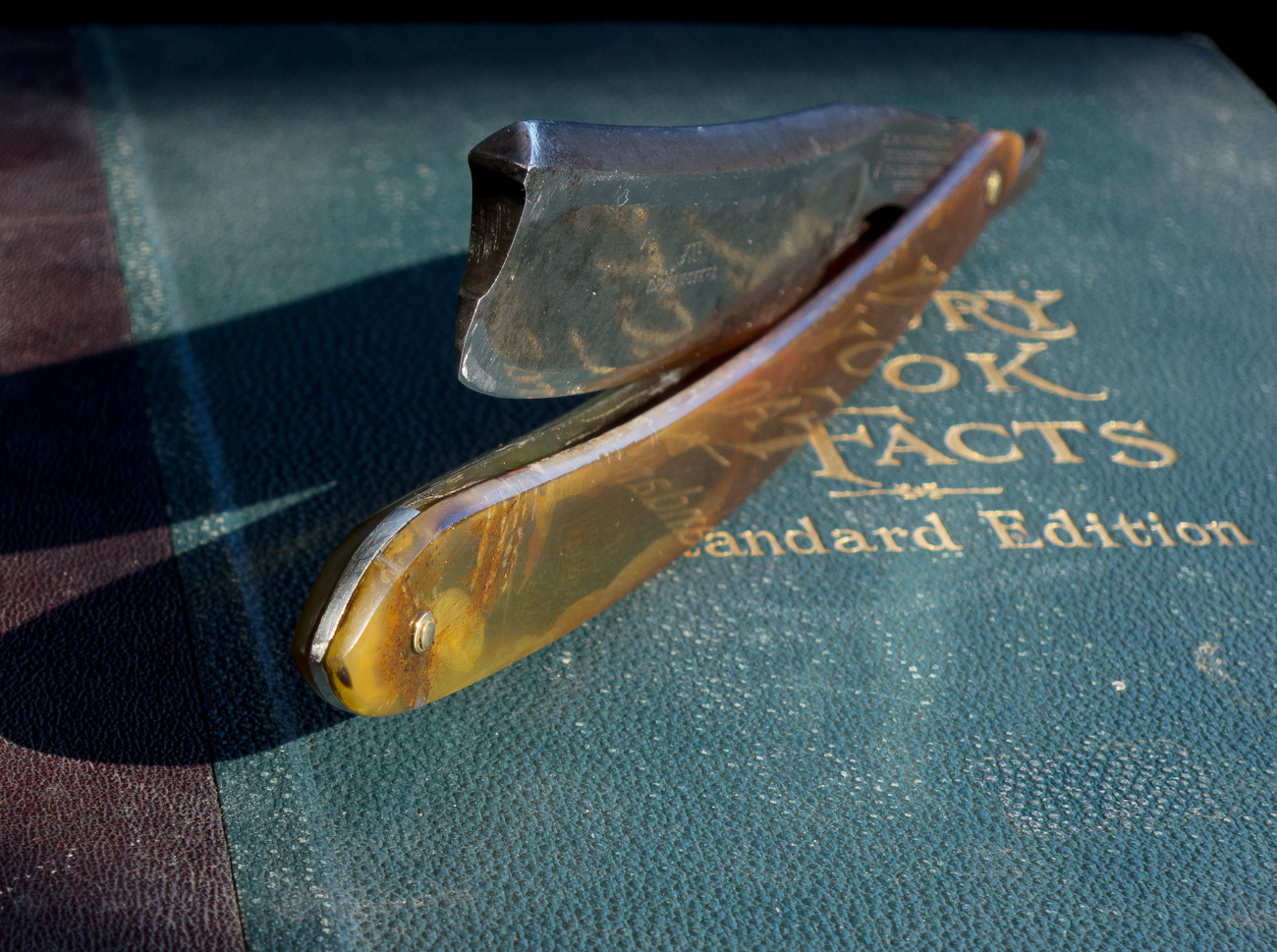

The scales were in pretty bad shape.

Of course, when I disassembled it, things broke.

As you can see, that break at the wedge end is badly glued and warped.

I think I can safely say you'll be surprised at how those scales cleaned up! My restoration strategy here was minimal. The patina on the blade was aesthetically appealing to me, and I knew that the 'wear in' on the scales, when they were fixed, cleaned and polished was going to be lovely.

Getting the scales lovely was hard work but well worth it, as you'll see in the next post.-Zak Jarvis. Writer. Artist. Bon vivant.

-

01-18-2013, 07:01 PM #2

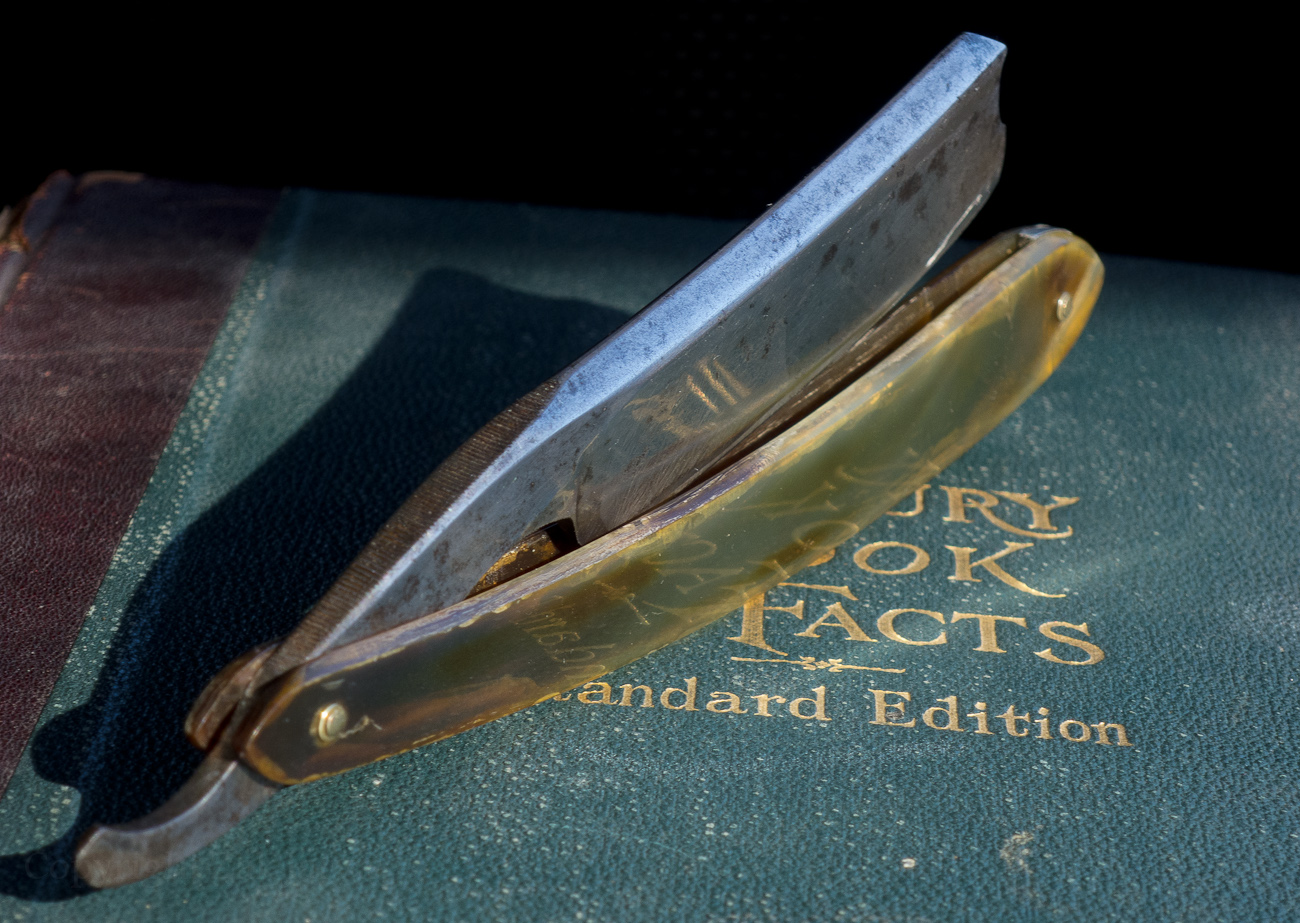

I honestly can't tell if the scales are tortoise shell or horn. Does it matter when they're this lovely?

Repairing the original break was complicated. First I had to straighten the scales, which I did using a clothes iron, water and my less-good Chinese hone. That took two or three rounds to get right (and the first time I tried I scorched the scales). Then I sanded and glued and epoxied and sanded and glued. I used filler made from horn dust. I mixed in powdered steel rust. I glued I sealed I sanded. Then I sanded some more with micromesh.

I had to reshape the wedge end because of the warping caused by that original crack. In the first post, it looks like there was a piece missing. There wasn't. The break at the pin had bent, and fixing that kind of warping was easier done by simply filling in the gap and grinding off the excess with the belt sander.

The end result looks, to my eye, an awful lot like amber. I might still take it apart and do a more thorough job with the wedge end. If I dug deeper holes to fill with CA/horn/rust, then took off a top layer of that, then sealed with a clear coat, it would be even prettier. Also, there's a tiny bit of delamination that happened around the pivot which I wouldn't mind sealing up. On the other hand, if I make the scales too pristine I'll need to clean the blade up further. As it is, I like the way both scales and blade wear their age.

As a neat bonus, one side exhibits lovely chatoyance.

That happens here because the material has delaminated slightly. The keratin fibers are long, like hair, and create very directional -- isotropic -- patterns within the material. The wavy lines you see in horn. But when those fiber bundles come apart inside the material, just a tiny, tiny bit, the air gap (even microscopic) has a different refractive power than the fibers -- birefringence. It's the same material property that causes the cats-eye effect in chrysoberyl, which is then technically called cymophane.

All that jargon is just a pathetic way of verbally capturing the beauty of light pouring through the scales like a river of honey.Last edited by Voidmonster; 01-19-2013 at 12:19 AM. Reason: IsoTROPIC, not Isotopic. Though I'm sure there are isotopes in there too.

-Zak Jarvis. Writer. Artist. Bon vivant.

-

01-18-2013, 07:12 PM #3

I imagine it was originally stained ox horn to look like tortoise.

When you clean those kinds of scales up them up like you did, you usually take off a lot of the stain they used on the surface and they just look like honey horn. Great job Zak, I love it!

When you clean those kinds of scales up them up like you did, you usually take off a lot of the stain they used on the surface and they just look like honey horn. Great job Zak, I love it!

Totally not trying to thread hijack -- but wanted to show you this one. Similar horns scales:

-

The Following User Says Thank You to Undream For This Useful Post:

Voidmonster (01-18-2013)

-

01-18-2013, 07:18 PM #4

Beautiful Flaws: Joseph Rodgers 'Indian Steel' restoration.

Beautiful Flaws: Joseph Rodgers 'Indian Steel' restoration.

Well done! I'm impressed that the epoxy joints have the mechanical strength for repining. So much nicer than it would have been buffed up and thrown into G10... Spew.

-

The Following User Says Thank You to EisenFaust For This Useful Post:

Voidmonster (01-18-2013)

-

01-18-2013, 07:19 PM #5

I'm not used to seeing the translucent horn done as flat scales, it's so much more commonly the rounded ones...

The surface grime on these made it impossible to tell what was originally on the outside. All of the surface darkening you see in my pictures was put there by me. The spot at the wedge end was to cover up the filler. The two in the middle of the pile side were... um... from scorching with the iron.

But there are also dimensional masses of different color inside the material, and when this stuff broke it did so very differently from horn. Almost like it was crystallized. Still, I think I'm just going to assume horn unless it's got obvious shell patterning inside.

Also, lovely job on that Rodgers, Brad!-Zak Jarvis. Writer. Artist. Bon vivant.

-

01-18-2013, 07:23 PM #6

-

01-18-2013, 07:29 PM #7The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,736

Thanked: 480

And people told me I was crazed for thinking it might be possible to repair horn scales! Pahh!

Fie on them, and Thank you Void, and you Undream for showing them (and me) how possible it is

-

The Following User Says Thank You to Magpie For This Useful Post:

Voidmonster (01-18-2013)

-

01-18-2013, 08:46 PM #8Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,780

- Blog Entries

- 1

Thanked: 4249

Very nice save , Zak, i enjoy seeing the time involved in repairing a lot more then pinning a new set of scales and bringing the blade to mirror finish on something that never was that way to begin with, Enjoy!

-

The Following User Says Thank You to Martin103 For This Useful Post:

Voidmonster (01-18-2013)

-

01-18-2013, 08:50 PM #9< Banned User >

- Join Date

- Feb 2011

- Posts

- 1,256

Thanked: 194

I just picked up this exact same razor...like it is 100% identical to the one in your pic. I am in the works of hand sanding it right now, my scales were not able to be saved so I am going to get some exotic wood for the blade. I can't wait to get this one done! yours is absolutely amazing! I love everything about the way it turned out. Thanks to everyone for sharing this thread. its great!!

-

01-18-2013, 11:56 PM #10

I'm impressed, nice work. I always wonder about the long-term durability of epoxy and superglue-based fixes. They seem structurally fine after I finish, but my examples have not been sitting around for years. Did you use the rust dust for coloring?

edit: I also know exactly what you mean by the crystallized feeling. I had a set of old scales on a JR that just crumbled when I took them off. They were definitely horn but didn't behave like usual, and had an almost leathery texture to them - looked exactly like your before pics. They had kind of warped and had a weird consistency that I could only, also, describe as resembling crystalline. Also I think you mean isotopic -> isotropic

Last edited by ScienceGuy; 01-19-2013 at 12:00 AM.

-

The Following User Says Thank You to ScienceGuy For This Useful Post:

Voidmonster (01-18-2013)

16Likes

16Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote