View Poll Results: Which edge do you prefer and why?

- Voters

- 68. You may not vote on this poll

-

Edge #1

3 4.41% -

Edge #2

49 72.06% -

Edge #3

8 11.76% -

Who cares?

8 11.76%

Results 91 to 100 of 105

-

04-28-2011, 12:16 PM #91

Blind Test

Blind Test

Yesterday i recieved my 3 razors back from Robert who was conducting a test. I will let Robert explain. So he honed them up without telling me how each was honed. Today was shave #1 of 3. I am doing a 2 pass shave,as this is how i judge my razors for sharpness and how close of a shave they provide. I will compair them to each other at the end. This one provided a smooth feel no irritation. I dont feel the Sharpness to be as high as it could.

Geneva cut

The Bomb New scent sample

-

The Following User Says Thank You to nicknbleeding For This Useful Post:

BladeRunner001 (04-28-2011)

-

04-28-2011, 12:45 PM #92

+1 Bernando "2. looks like a J-nat finish" My choice as well. Great pics, thank you.

-

The Following User Says Thank You to BanjoTom For This Useful Post:

BladeRunner001 (04-28-2011)

-

04-30-2011, 05:49 AM #93

Alright gentlemen,

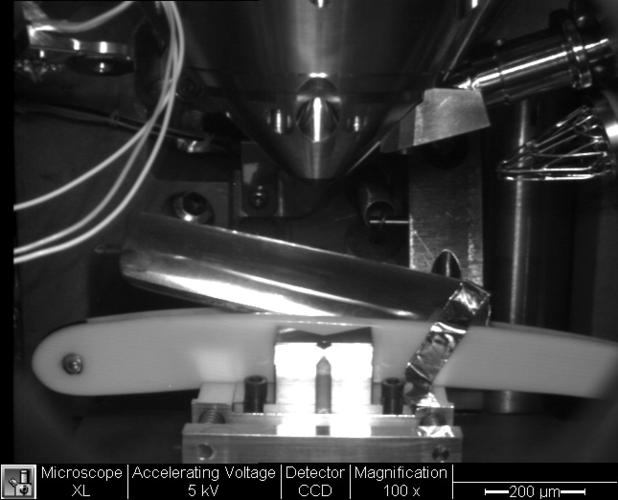

As promised, my friend and I ran some initial images of my Shapton edges under the SEM and that didn't look good. Not from the standpoint of the edge, but the fact that the metal was being so magnetized and absorbing all the electrons that it looked dark. No resolution could be made out. So, we gave up and I took the blade and ran them with my naniwas. Gave the process another try. 100% improvement (but still not ultra satisfactory...this metal is problematic for the SEM). Below are the images.

Also, for kicks, we took the picture of a manufactured sharp edge (like persona DE blade...last shot). You can see the difference. Also, you can see the scale bar at the lower right hand corner for resolution

A.

Razor: W.J. Donovan "Gee Whizz"

Honing: Naniwa 1k, 5k, 8k, 12k

200µm resolution SEM:

50µm resolution SEM:

20µm (1,500X mag) resolution SEM:

5µm (6,200X mag) resolution SEM:

2µm (15,000X mag) resolution SEM:

1µm (30,000X mag) resolution SEM:

B.

Razor: Persona DE Blade

Honing: manufacturer's edge

See these last 2 pictures in next post (can only include 7 images per post...sorry guys)

The naniwa provided an exceptionally smooth bevel (see 50µm res image in (A)) and an amazingly sharp edge (see 2µm and 1µm res images in (A)). The edge is an astonishing ~100nm (10^-9 m) thick (or thin)...That's sharp!!! The scratch pattern on the bevel is obvious. You can see this difference between the blade and bevel in the 200µm image in (A). Furthermore, you can see the scratch marks (from the X-strokes) converging on the edge in the 2µm and 1µm images in (A).

Series (B) provides images for a control, manufactured blade. The pictures don't look as good because of the oil on the blade (even though I cleaned it thoroughly with ethanol). The edge is a bit sharper and straighter than my honing, but the metal is different. What is observed in the manufactured edge is "crystalline metal particles" (see 2µm res image in (B)). the straight scratch patterns of the bevel are also obvious in the 100µm image in (B).

At some point, I will redo this experiment (same razor) with the JNat honing progression and see if any different. All in all, I am happy with the edge and the results...However, I will NOT test shave with this razor as it was in pretty rusty and in pitted condition. The rotting can be seen as the 3 dark spots on the bevel in the 200µm image in (A).

I hope you guys like these shots. Sorry if some are not 100% focused (magnetization of metal caused some problems with focusing)

Sham: Those "True" edges are for you maestro

-

The Following 5 Users Say Thank You to BladeRunner001 For This Useful Post:

baldy (05-02-2011), BigJim (05-13-2011), leadingedge (05-13-2011), nicknbleeding (04-30-2011), Tolly (04-30-2011)

-

04-30-2011, 05:51 AM #94

Last 2 picture (series B - Persona DE blades)

100µm resolution SEM:

2µm (13,700X mag) resolution SEM:

-

The Following 7 Users Say Thank You to BladeRunner001 For This Useful Post:

baldy (05-02-2011), BigJim (05-13-2011), Birnando (04-30-2011), eTom (04-30-2011), leadingedge (05-13-2011), nicknbleeding (04-30-2011), Zelenbakh (04-30-2011)

-

04-30-2011, 07:32 AM #95

Awesome pics Robert. You should lay a hair across some of the next pics for perspective . Probably look like a pine tree

“The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.”

“The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.”

-

04-30-2011, 01:05 PM #96

Last edited by BladeRunner001; 04-30-2011 at 04:53 PM.

-

The Following User Says Thank You to BladeRunner001 For This Useful Post:

onimaru55 (05-01-2011)

-

04-30-2011, 01:53 PM #97

Very nice Robert!

Thanks for putting them up here.

Very interesting pictures.

It sure does give a better understanding of what really happens with the steel while honing, and also why stropping is a good thing

Weird to see the flaking off of the manufactured blade!

Great work, buddy!!Bjoernar

Um, all of them, any of them that have been in front of me over all these years....

-

The Following User Says Thank You to Birnando For This Useful Post:

BladeRunner001 (04-30-2011)

-

04-30-2011, 05:07 PM #98

Thank you Birnando,

Stropping will probably smooth out the edge considerably and that is a very very good thing before we shave. The edge (as it is here) ain't all that bad considering that we are looking the the edge under 30,000X magnification. If I laid a hair on top of this edge (like Oz suggested for perspective), it will look like a darn baobab tree (HUGE). Considering that hair is on average ~100-120µm in diameter and the edge in these photos is ~0.1µm thick, hair will look 1000X bigger (at that magnification).

The flaking is due to Crystalline Metal forming on the edge. These form when metal atoms are surrounded by a sea of valence electrons, which are given by the metal atoms and belong to the crystal as a whole.

-

04-30-2011, 06:33 PM #99

Thank you for posting these pictures. I find SEM pics of blade edges fascinating!

-

05-01-2011, 12:53 AM #100

Ok so today is the 2nd shave of Roberts test. I am using the same cream for the test to keep it consistant. I am also only doing 2 passes. This shave was much better than the first. Its was a GREAT shave. On the last shave i will compare all 3 Blades!

Tony miller strop "only used after the shave"

Vestavia Brush

The BOMB Calypso

-

The Following 2 Users Say Thank You to nicknbleeding For This Useful Post:

baldy (05-02-2011), BladeRunner001 (05-01-2011)

29Likes

29Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote